Brazed-plate heat exchangers (BPHEs) are well-known for their stylish style as well as superior efficiency and long-lasting. These are the reasons they’re a staple across a variety of industrial processes. This post will focus on the fundamentals that brazed plate heat exchangers follow as well as their benefits as in how they’re used across various sectors. Additionally, we’ll talk about the significance of screw vacuum pumps for increasing the efficiency of BPHE systems.

What is a Brazed Plate Heat Exchanger?

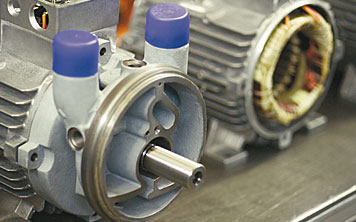

Brazed plate heat exchanger a collection of corrugated, small plates that stack and create various channels that allow for the flow of fluid. They are filled with filler material, typically made of copper or nickel to create the unit durable, closed and does not require gaskets. Their primary function is to transfer the heat effectively across two fluids and the vast surface that the plates cover.

Components and Design

Plates

The components of the components of a BPHE generally consist of stainless steel due to its remarkable thermal conductivity and resistance against corrosion. Each plate is made together specific corrugations for generating turbulent flow. This enhances the efficiency for heat transfer.

Brazing Material

They are then bonded to the brazing material, for instance, copper or nickel. The brazing substance is heated to the point that it is melting creating strong bonds between plates and providing a leak-proof and strong structure.

Inlet and Outlet Connections

The BPHEs come with outlets and connection to the inlet of fluids. They are able to be easily integrated with different systems. Connectors are threaded or flanged according to the specifications for the specific use.

Advantages of Brazed Plate Heat Exchangers

Compact Size

The BPHEs are incredibly compact due the stacking plate design and favor a large surface that can be used for heating inside smaller areas. This is the reason they can utilize in locations where there is a need for a large spaces.

High Efficiency

The layout that the plate is shaped with corrugations improves the turbulence in the flow, and greatly improves the efficiency of energy transfer. This efficiency is essential in situations where you need the best performance in thermal efficiency.

Durability

The brazed design of BPHEs minimizes the need of gaskets, thereby decreasing the risk of leaks and in reducing the necessity to maintain. Strong brazed joints ensure the strength and durability of the product as time passes.

Versatility

The BPHEs are capable of operating with various temperatures and pressures and are therefore suitable to a wide range of applications. They work using a range of fluids, including refrigerants and oils, as well as chemicals.

Applications of Brazed Plate Heat Exchangers

HVAC Systems

For heating and ventilation, as well as air conditioning (HVAC) system, BPHEs are used for their cooling functions and warming. Their size is tiny and their efficiency ensure they are appropriate to be used in chillers, heat pumps as well as air conditioning units.

Refrigeration

BPHEs are commonly used in refrigeration equipment, such in evaporators and condensers. Their capability to stand up to extreme pressures and temperatures is what makes them suitable for the modern needs of refrigeration.

Industrial Processes

The BPHEs are utilized for a range of industrial processes like the chemical industry, as in the oil and gas industry and power generation for heating and cool liquids. Their endurance and efficacy makes them suitable for industrial environments that are harsh.

Renewable Energy Systems

BPHHEs are crucial to the renewable energy sources, such as solar thermal or geothermal energy system. Their efficiency is extremely high, which enhances the transfer of energy and increases effectiveness and durability of these techniques.

Enhancing the Performance of BPHE by together the Screw Vacuum Pumps

They play a vital part in improving the performance of brazed plates that are used as heat exchangers. Through the production of a vacuum, they reduce the temperature of liquid and, consequently, boost the effectiveness in heat exchange. This is the reason why screw vacuum pumps can be integrated into BPHE equipment:

Evaporation Processes

For Evaporation where pump vacuums together screw are employed to reduce the boiling point of the fluid, which outcome in less pressure as well as operating temperatures. This enhances efficiency of heat transfer while reducing the use of energy and operating costs.

Condensation Processes

If it’s condensation using pump vacuums that are screw-driven, they can create the conditions necessary for efficient condensing even at lower temperature. This outcome is improved efficiency for the heat exchanger as well as lessening the load placed on parts that make up the entire system.

Degassing

These are used to eliminate the gas in fluids before they are allowed to be absorbed by BPHE. The removal of gases from fluids reduces the risk of cavitation and also ensures the proper running of the system which improves the effectiveness the exchanger can achieve.

Conclusion

The Brazed Plate heat exchangers are highly robust and flexible devices that are essential in many industrial procedures. Their size and compactness along with their high performance and durability make the perfect choice for HVAC, refrigeration and industrial processes, as in environmentally sustainable energy solutions. The incorporation of screw vacuum pumps within BPHE equipment will increase the efficiency of their systems by increasing the efficiency of heat transfer, while also reducing consumption of energy. Through understanding the functions and advantages of brazed-plate heat exchangers firms can pick the most suitable design of heat exchanger which fulfills their specific requirements. provide the highest effectiveness and efficiency.

Daily Blogger News Stay updated with the latest trends and insights. Your reliable source for daily updates and information.

Daily Blogger News Stay updated with the latest trends and insights. Your reliable source for daily updates and information.